India wire and cable manufacturing industry has seen remarkable growth over the last few decades. As one of the fastest-growing economies in the world, India development is closely tied to its ability to produce high-quality wires and cables for a range of applications. From ensuring power transmission to enabling communication networks, these essential components form the backbone of the national infrastructure. This blog will explore the growing wire and cable manufacturing industry in India, the technological innovations within the sector, and its critical role in powering industrial growth, urbanization, and the future of India.

Wires and cables are the heart of an electrical system, enabling the transmission of power and communication signals. They are used in virtually every sector, from power generation to telecommunications, construction, and industrial manufacturing. India, as a hub of industrial activity, requires a steady supply of high-quality wires and cables for sectors like energy, construction, automotive, telecommunications, and aerospace. As urbanization accelerates and new infrastructure projects emerge, the demand for these products is on the rise.

The Indian wire and cable industry is diverse, manufacturing a range of products including power cables, control cables, telecom cables, instrumentation cables, and more. These products are essential for both urban and rural developments, playing a vital role in creating smarter cities, improving connectivity, and increasing power generation capacities across the nation.

1. Increasing Infrastructure Investments: The Indian government has made significant investments in infrastructure projects, such as metro systems, airports, smart cities, and roads. These projects require a vast amount of wiring and cabling to support power distribution, communications, and safety systems. Additionally, initiatives like "Atmanirbhar Bharat" (Self-Reliant India) and "Make in India" aim to reduce dependence on imports and boost local manufacturing, which further accelerates the growth of the wire and cable industry.

2. Rising Energy Demand: India increasing demand for electricity due to population growth, industrialization, and digitalization necessitates an expansion of its power infrastructure. Wires and cables are essential for power transmission and distribution, both in urban and rural settings. The government's focus on rural electrification and the establishment of a robust national grid system further drives demand for high-quality wires and cables.

3. Technological Advancements: With technological advancements, the wire and cable manufacturing sector in India has seen improvements in materials and production processes. Manufacturers are adopting automation, robotics, and advanced manufacturing techniques to increase efficiency, reduce costs, and improve product quality. Moreover, the use of innovative materials, such as environmentally friendly insulation and low-smoke, zero-halogen cables, is growing as environmental concerns become more pronounced.

4. Increasing Industrialization and Automation: India is becoming an industrial hub, with industries like automotive, electronics, and textiles expanding rapidly. As industries adopt automation and advanced machinery, the need for specialized cables has grown. From industrial automation to robotics and power systems, these cables ensure smooth functioning by transmitting power, data, and signals efficiently and safely.

5. The Growth of Renewable Energy: With India commitment to reducing its carbon footprint, renewable energy projects, including wind, solar, and hydroelectric power plants, are gaining momentum. These projects require specialized wires and cables to ensure power generation and distribution processes are safe and efficient. The growth of renewable energy is expected to continue driving demand for specialized cables, contributing to the overall growth of the wire and cable manufacturing sector in India.

India wire and cable manufacturers produce a wide range of products to meet the growing needs of different industries. Some of the most commonly produced types of wires and cables include:

1. Power Cables: These are used to transmit electrical power from power stations to homes, industries, and other establishments. Power cables can be low-voltage or high-voltage, depending on the application. They are usually made from copper or aluminum, with copper being preferred for its higher conductivity and better efficiency.

2. Control Cables: These cables are used in industrial applications to control and monitor machines, electrical devices, and circuits. Control cables are designed to handle lower voltage and are essential for industrial automation systems. They ensure the safe and effective operation of control circuits, sensors, and machinery.

3. Telecommunication Cables: Telecommunication cables, including fiber-optic cables, are designed to transmit data and voice signals. Fiber-optic cables are especially important for high-speed internet connectivity and telecommunication networks, offering superior bandwidth and data transmission speeds compared to traditional copper cables.

4. Instrumentation Cables: These cables are used in industrial settings where monitoring and controlling instruments is necessary. They are typically used in environments that require high precision, such as in the oil and gas industry, chemical plants, and power stations. Instrumentation cables are designed to carry low-level signals and are resistant to environmental factors like temperature and moisture.

5. Flexible Cables: Flexible cables are used in dynamic environments where constant movement and bending of cables are required. These cables are commonly used in home appliances, machinery, and robotics, where flexibility and durability are key requirements.

6. House Wiring Cables: These cables are used for residential wiring applications to power electrical appliances, lights, and outlets. They come in different sizes and insulation ratings, depending on the load capacity required for the specific installation.

7. Building Wires: These are used in construction projects to provide the electrical infrastructure in residential, commercial, and industrial buildings. These wires need to meet specific safety standards and are designed for use in dry, damp, or wet locations depending on the application.

The role of wire and cable manufacturers in India goes beyond just providing essential electrical components. These products are vital to ensuring that industries can operate efficiently, safely, and productively. Manufacturers supply cables and wires for:

As environmental awareness grows, wire manufacturers in India are adopting eco-friendly practices to reduce their impact on the environment. These measures include:

1. Eco-friendly Materials: Many manufacturers are focusing on using recyclable materials such as copper, aluminum, and eco-friendly insulation that minimizes the impact on the environment. They are also adopting lead-free cables and reducing the use of harmful substances such as halogen.

2. Energy-Efficient Manufacturing: Manufacturers are making efforts to reduce energy consumption during the production process by implementing energy-efficient machinery and optimizing production lines.

3. Waste Management and Recycling: The wire manufacturing process produces waste materials, and manufacturers are working to recycle scrap metals, cables, and other materials to minimize waste and reduce costs.

The future of the wire and cable industry in India looks promising as the country continues to invest in infrastructure, renewable energy, and industrial growth. Key trends influencing the future of the sector include:

Wire and cable manufacturing is a critical sector in India economy, powering everything from residential homes to massive industrial operations. With continued investment in infrastructure, technology, and innovation, the future of the industry looks bright. As India moves towards becoming a global manufacturing hub, the wire and cable sector will play a significant role in powering the country's growth, development, and sustainability.

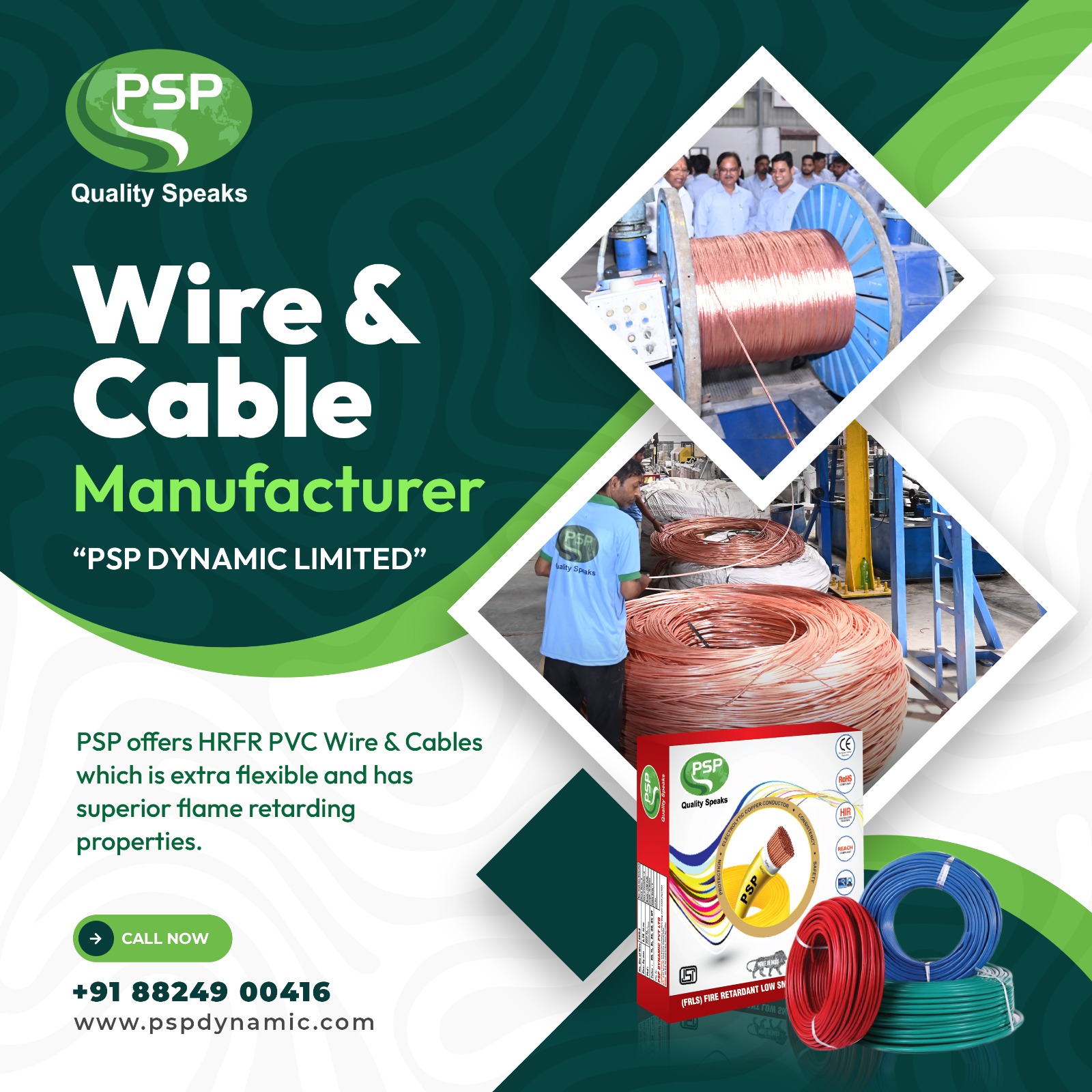

PSP Dynamic Limited, a key player in India wire and cable manufacturing industry, is committed to providing high-quality products that meet international standards, supporting the country push towards modernization and industrial excellence.

You might like this product!